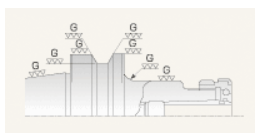

Super Balancing

Balancing is another indispensable factor for high speed cutting work.

The over-all surface grinding from the V-flange’s face to the holder’s neck brings forth the high balancing, enabling even the standard model to be used for a high rotation machining up to 25,000min-1.

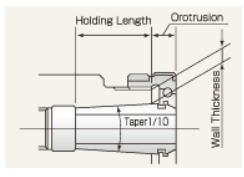

Super Rigidity Super Grip Force

Besides the precision, the gripping force and the rigidity are also indispensable for high speed and high efficient cutting.

This high rigidity is realized by minimizing collet’s protrusion from the holder and also by increasing the wall thickness of the collet insertion hole of the holder.

This grip force is increased by 1.5 times compared to that of our YCC collet, making this Super G1 Chuck suitably function even for the high speed machining work by the end-mill.

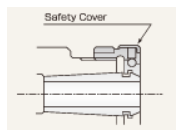

Safety

Usually the steel balls in the lock-nut are screw plugged not to fall out.

Our lock-nut has an additional safety cover, made of steel, press-fitted on the outer circumference with its edges caulked in and, thus, safely usable in high rotation work.

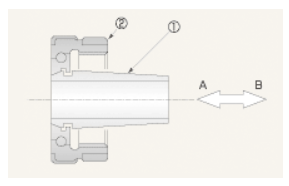

Simple and Ensured On-Off of Collet

Only by pushing the collet 1.in A direction, the collet will be set in the lock-nut 2.Removing of the collet is only to pull the collet in B direction. No jigs are required.

How to set the tool on the chuck: Put the collet 1 in the lock-nut 2 →set the lock-nut+collet on the holder →insert the tool into the collet 1 →fasten the lock-nut 2.

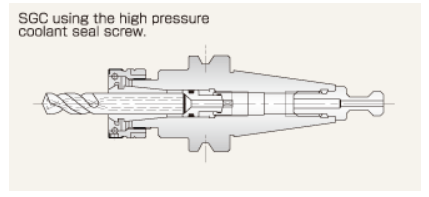

With the coolant seal screw,the chuck can use the high pressure coolant(spindle-through type)

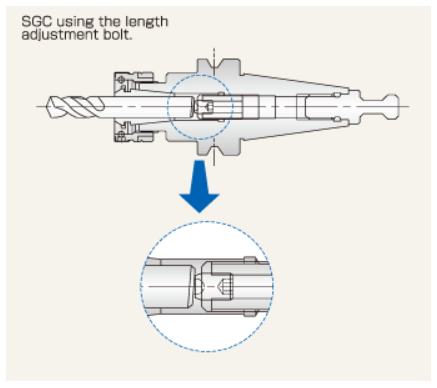

The length adjustment bolt of APM type secures the high runout accuracy by preventing tool inclination.