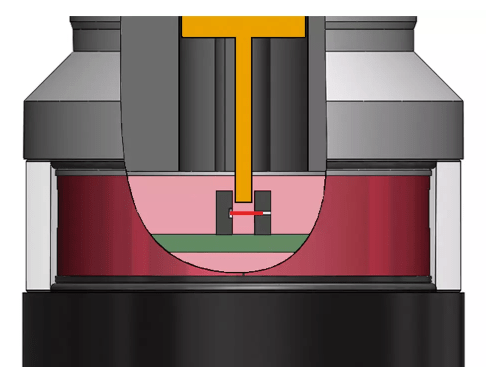

Wear-free and optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables higher measuring speeds and accuracy than with conventional probes

- Reliable tool setting under the most adverse conditions

- Wear-free with long-term stability

High-precision and modern measuring mechanism

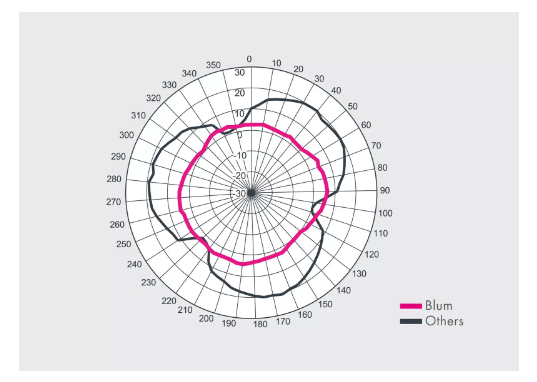

- Precise, non-lobing switching behaviour

- Constant deflection forces

- High-quality latest-generation BLUM measuring mechanism

- No disadvantageous 3-leg principle

- No highly sensitive switching elements

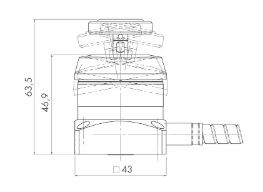

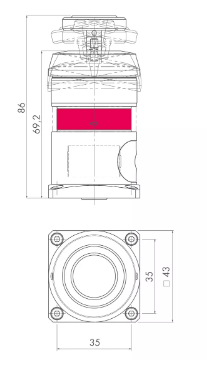

Tool setting probe ZX-Speed

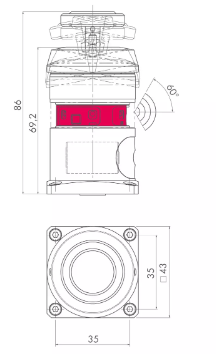

Tool setting probe ZX-Speed IR

Tool setting probe ZX-Speed RC

Additional product features

- Max. probing speed: 2 m/min

- Repeatability: 0.4 μm 2σ (standard)

- Min. tool diameter: 1 mm*

- Protection class IP68

- Exchangeable measuring surface

- Extremely robust